The world’s largest 3D printer is right here in SA, and it is already at work turning powder into large metal components for the aerospace sector.

The printer — or more accurately, a metal additive manufacturing system — is housed at the Council for Scientific & Industrial Research (CSIR) in Pretoria. It is part of Aeroswift, a project funded by the science & innovation department to industrialise and commercialise the printer’s technology. It cost R100m to build.

The CSIR and Aerosud Innovation Centre — a subsidiary of aircraft manufacturer Aerospace Development Corp — saw the potential of this technology as far back as 2011, and have since designed, built and manufactured an advanced 3D printer — all in SA.

The CSIR hopes to secure contracts with international suppliers, and thanks to an existing relationship with Airbus, is in negotiations to print parts for the European aircraft maker.

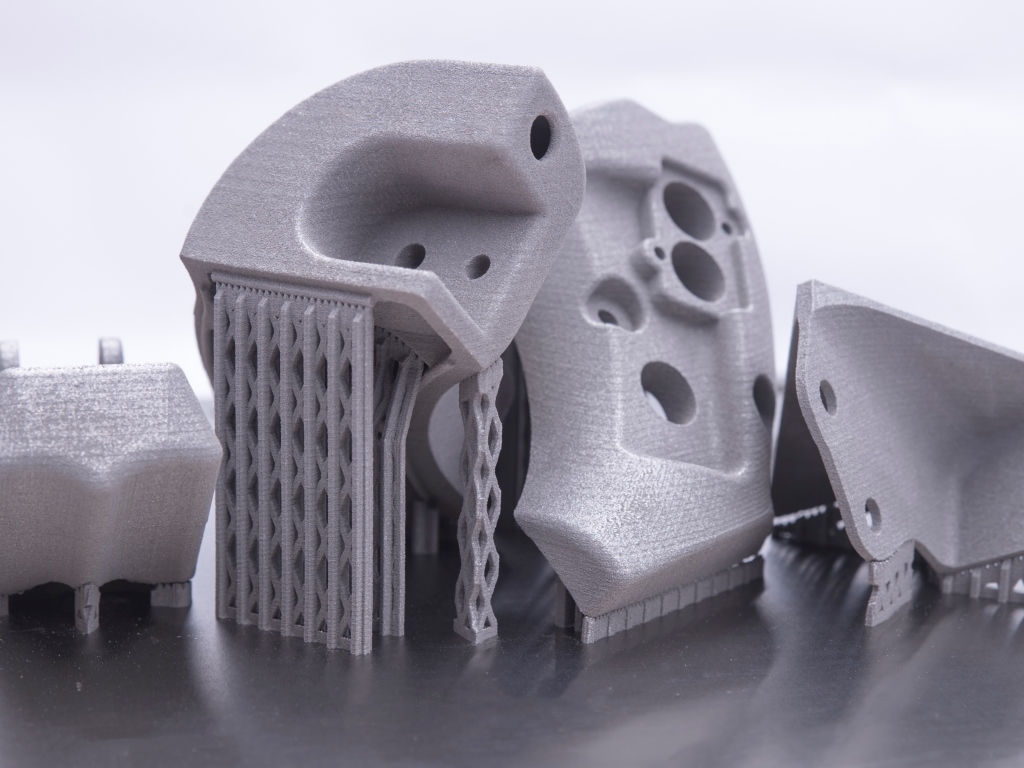

Additive manufacturing is a relatively new manufacturing technology. It is considered one of the key technologies that will support the production of high-value parts for industries such as aerospace. Additive manufacturing fuses materials together, layer by layer, into 3D functioning parts that are lighter and stronger than standard parts.

The 3D printer uses lasers to melt titanium powder to produce the metal parts.

The 3D printer can print components up to 2m long, 600mm wide and 600mm high. The CSIR says the Aeroswift team developed new technologies to upscale the additive process to go faster and larger than other systems, and achieved production speeds of up to 10 times faster than current commercial laser melting machines.

This is due to the 3D printer using a 5kW laser – compared to commercial machines powered with 800W. It is able to print four designs at the same time.

According to NAFISA AKABOR. (Source: BUSINESSLIVE.CO.ZA)